- Badallan pit

- Badallan No.2 mine

- Balbardie - old pits

- Balbardie No.1 pit

- Balbardie No.2 pit

- Balbardie No.2 mine

- Balbardie No.4 pit

- Balbardie No.5 pit

- Ballencreiff fireclay mine

- Ballencrieff - early pits

- Barbauchlaw - early pits

- Barbauchlaw No.1 pit

- Barbauchlaw No.2 pit

- Barbauchlaw No.3 pit

- Barbauchlaw No.4 pit

- Barbauchlaw No.5 pit

- Barbauchlaw No.7 pit

- Barbauchlaw No.9 pit

- Barbauchlaw No.11 pit

- Barbauchlaw No.10 pit

- Barbauchlaw No.12 pit

- Barbauchlaw No.13 pit

- Barbauchlaw No.14 pit

- Barbauchlaw No.15 pit

- Barbauchlaw No.16 pit

- Barbauchlaw No.17 pit

- Barbauchlaw No.18 pit

- Barbauchlaw No.19 pit

- Barbauchlaw No.23 pit

- Barbauchlaw Fireclay and Coal Mine

- Bathgate - old pits

- Bathville No.1 pit

- Bathville No.3 pit

- Bathville No.4 pit

- Bathville No.5 pit

- Bathville unidentified pit 1

- Bathville unidentified pit 2

- Bathville unidentified pit 3

- Benhar (Addie) No.2 pit

- Benhar No.6 and No.14 pits

- Benhar Colliery

- Benhar No.18 pit

- Benhar No.19 pit

- Benhar No.21 pit

- Benhar No.3 pit

- Benhar No.5 pit

- Benhar - old pits

- Benhar unidentified pits

- Benthead No.1 mine

- Benthead unidentified pit 1

- Benthead unidentified pit 2

- Benthead unidentified pit 3

- Benthead unidentified pit 4

- Benthead unidentified pit 5

- Benthead unidentified pit 6

- Bents mine

- Birniehill mine

- Blackrigg No. 1 & 2

- Blackrigg No.3 pit

- Boghead No.1 pit

- Boghead No.2 pit

- Boghead No.3 pit

- Boghead No.4 pit

- Boghead No.5 pit

- Boghead No.6 pit

- Boghead No.8 pit

- Boghead No.9 pit

- Boghead No.10 pit

- Boghead No.11 pit

- Boghead No.12 pit

- Boghead No.14 pit

- Boghead No.15 pit

- Boghead No.25 mine

- Braehead No. 1 pit

- Braehead No.2 pit

- Bridgecastle - early pits

- Bridgehouse - old pits

- Bridgehouse pit

- Brucefield pit

- Camps pit

- Cappers No.1 pit

- Cappers No.2 pit

- Cappers No.3 pit

- Cappers No.4 pit ?

- Colinshiel No.1 pit

- Colinshiel No.2 pit

- Colinshiel No.3 pit

- Colinshiel No.4 pit

- Cowdenhill No.1 Pit

- Craigrigg pit

- Crofthead (Stonehead) No.1 pit

- Crofthead No.2 pit

- Crofthead No.3 pit

- Crofthead No.5 & 6 pit

- Crofthead No.7 pit

- Crofthead (Stonehead) No.7 pit

- Cult pit

- Cultrigg No.1 & No.2 pits

- Cultrigg No.3 pit

- Cultrigg No.4 pit

- Cuthill mines

- Drumcross pits

- Drum No.1 & 2 pits

- Dumback No.1 mine

- Dumback No.2 mine

- East Benhar No.2 mine

- Eastfield No.1 ironstone pit

- Eastfield No.3 ironstone pit

- Eastfield No.3 coal pit

- Eastfield No.4 ironstone pit

- Eastfield No.5 pit

- Eastfield No.6 pit

- Eastfield No.8 ironstone pit

- Eastfield Eagin pit

- Eastfield Engine pit

- Eastfield unidentified pit 1

- East Handaxwood fireclay mine

- Easton No.1 pit

- Eastrigg (Craigrigg) No.1 pit

- Eastrigg (Craigrigg) No.2 pit

- Eastrigg (Craigrigg) No.3 pit

- Fallahill No.3 pit

- Fallahill No.4 pit

- Fauldhouse No.1 pit

- Fauldhouse No.1 (Knowes) pit

- Fauldhouse No.5 pit

- Fauldhouse No.8 pit

- Fauldhouse No.9 pit

- Fauldhouse No.10 pit

- Fauldhouse No.11 pit

- Fauldhouse No.13 pit

- Foulshiels No.1 & No.2 pits

- Gormyre mine

- Goukstane pit

- Greenburn pit

- Greenrigg pit

- Handaxwood No.1 pit

- Handaxwood No.2 pit

- Handaxwood No.3 pit

- Handaxwood No.4 pit

- Handaxwood No.5 pit

- Handaxwood early pits

- Handaxwood unidentified pit 1

- Handaxwood unidentified pit 2

- Handaxwood unidentified pit 3

- Handaxwood unidentified pit 4

- Handaxwood unidentified pit 5

- Handaxwood unidentified pit 6

- Handaxwood unidentified pit 7

- Handaxwood unidentified pit 8

- Handaxwood unidentified pit 12

- Handaxwood unidentified pit 13

- Handaxwood unidentified pit 14

- Handaxwood unidentified pit 15

- Harburn limestone mine

- Harthill No.1 ironstone pit

- Hartrigg or Harthill No.3

- Hartrigg No. 4 & 5 pit

- Heads mine

- Heatherfield No.4 pit

- Heatherfield No.5 pit

- Heatherfield No.6 pit

- Heatherfield No.7 pit

- Hilderston Hill pit

- Hilderston - early pits

- Hopetoun No.2 pit

- Heatherfield No.3 pit

- Hopetoun No.8 pit

- Hopetoun No.9 pit

- Hopetoun No.10 pit

- Hopetoun No.11 pit

- Hopetoun No.12 & 13 pits

- Inchcross No.1 pit

- Inchcross No.2 pit

- Kipps - early pits

- Knowton No.1 & 2 pits

- Latchburn pit

- Leadloch No.1 pit

- Leadloch No.2 pit

- Levenseat No.1 limestone pit

- Levenseat No.2 pit

- Levenseat No.3 limestone pit

- Levenseat No.3 fireclay mine

- Levenseat No.4 fireclay mine

- Levenseat No.1 & 2 fireclay mine

- Levenseat High mine

- Levenseat No.1 limestone mine

- Levenseat quarry limestone mines

- Levenseat unidentified mine

- Loganlea No.1 pit

- Loganlea No.2 pit

- Longford pit

- Mosside No.1 Pit

- Mosside No.2 pit

- Mosside No.3 pit

- Mosside No.4 mine

- Muckraw mine

- Muirhousedyke pit (1)

- Muirhousedyke pit (2)

- Muldron No.6 pit

- Muldron No.7 pit

- Muldron No.8 pit

- Muldron No.9 pit

- Muldron unidentified pit 1

- Muldron unidentified pit 2

- Muldron unidentified pit 3

- Muldron unidentified pit 4

- Muldron unidentified pit 5

- Muldron unidentified pit 6

- Muldron unidentified pit 7

- Muldron unidentified pit 8

- Muldron unidentified pit 9

- Muldron unidentified pit 11

- Muldron unidentified pit 10

- Muldron unidentified pit 12

- Murieston Limestone Mine

- Murraysgate mine

- North Cobbinshaw coal mine

- Northrigg No.2 pit

- Northrigg No.7 pit

- Northrigg No.1 mine

- Northrigg No.2 mine

- Polkemmet No.5 pit

- Polkemmet No.6 pit

- Polkemmet No.8 pit

- Polkemmet No.9 pit

- Polkemmet Colliery

- Polkemmet No.3 pit

- Polkemmet unidentified pit 1

- Polkemmet unidentified pit 2

- Polkemmet unidentified pit 3

- Polkemmet unidentified pit 4

- Pottishaw No.1 & 2 mine

- Redhouse pit

- Riddochhill No.1 pit

- Riddochhill No.2 pit

- Riddochhill Almond Mines

- Snab pit

- South Broadrigg pit

- Southrigg No. 1 & 2 pits

- Southrigg No. 3 & 4 pits

- Southrigg No. 7 & 8 pits

- Standhill No.1 pit

- Standhill No.2 pit

- Starryshaw No.1 & 2 pits

- Stonehead mine

- Stonehead No.1 pit

- Stonehead No.2 pit

- Stoneheap limestone pit

- Stoneyburn No.1 pit

- Stoneyburn No.2 pit

- Tippethill No.1 & 2 mine

- Torbane No.1 pit

- Torbane No.2 pit

- Torbane No.3 pit

- Torbanehill No.1 pit

- Torbanehill No.2 pit

- Torbanehill No.3 pit

- Torbanehill No.4 pit

- Torbanehill No.5 pit

- Torbanehill No.6 pit

- Torbanehill No.7 pit

- Torbanehill No.8 pit

- Torbanehill No. 9 pit

- Torbanehill No.10 pit

- Torbanehill No.11 pit

- Torbanehill No.12 pit

- Torbanehill No.13 pit

- Torbanehill No.14 pit

- Torbanehill No.15 pit

- Torbanehill No.16 pit

- Torbanehill No.17 pit

- Torbanehill No.18 pit

- Torbanehill No.19 pit

- Torbanehill No.20 pit

- Torbanehill No.21 pit

- Torbanehill No.24 pit

- Torbanehill No.26 pit

- Torbanehill No.29 pit

- Torbanehill Garden Pit

- Trees No.1 pit

- Trees No.2 pit

- Trees No.3 pit

- Wallhouse No.1 mine

- Westallan pit

- Westfield No.1 pit

- Westrigg No.1 pit

- Westrigg No. 2 & 3 pit

- Whitrigg No. 1 & 2 pits

- Whitrigg No. 4 Burnbrae mine

- Whitrigg No. 5 pit

- Whitrigg No.8 & 9 mine

- Woodbank Mine

- Woodend No.1 pit

- Woodend No.2 pit

- Woodend No.3 pit

- Woodend No.4 pit

- Woodend No.5 pit

- Woodmuir No.1 pit

- Woodmuir No.2 pit

- Woodmuir No.3 pit

- Woodmuir No.4 pit

- Woodmuir - early pits (south)

- Woodmuir - early pits (north)

Mosside No.1 Pit

Pit in the lands of Mosside reaching the Balbardie coal at 32 fathoms and Bathgate Main coal at 69 fathoms. Workings linked to Boghead pit.

The 1883 List of Mines records Mosside No.1, owned by Gavin Paul, manager Walter Annan, working the Balbardie coal by the longwall method, employing 21 on the surface and 60 underground. The downcast shaft was 16' x 6' and 200 ft deep, the upcast was 8' x 6' and 96 feet deep. It was a non-fiery mine ventilated by a fan 14 ½' diameter.

The 1885 List of Mines records Mosside No.1, owned by Gavin Paul, manager Walter Annan, working the Balbardie, 6' Shaley, and 3' coal by the longwall method, employing 23 on the surface and 55 underground. The downcast shaft was 14' x 6' and 198 ft deep, the upcast was 14½' x 6' and 96 feet deep. It was a non-fiery mine ventilated by a fan 14 ½' diameter.

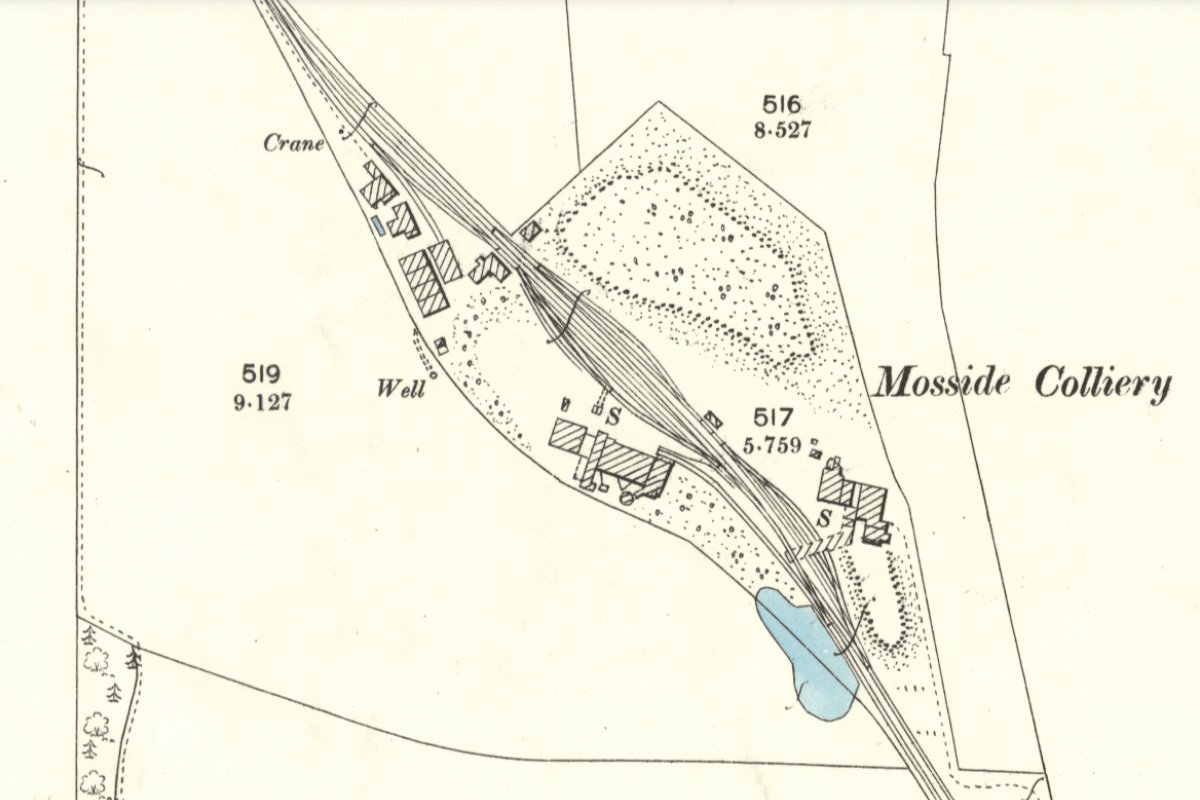

25" OS map c.1895, Courtesy National Library of Scotland

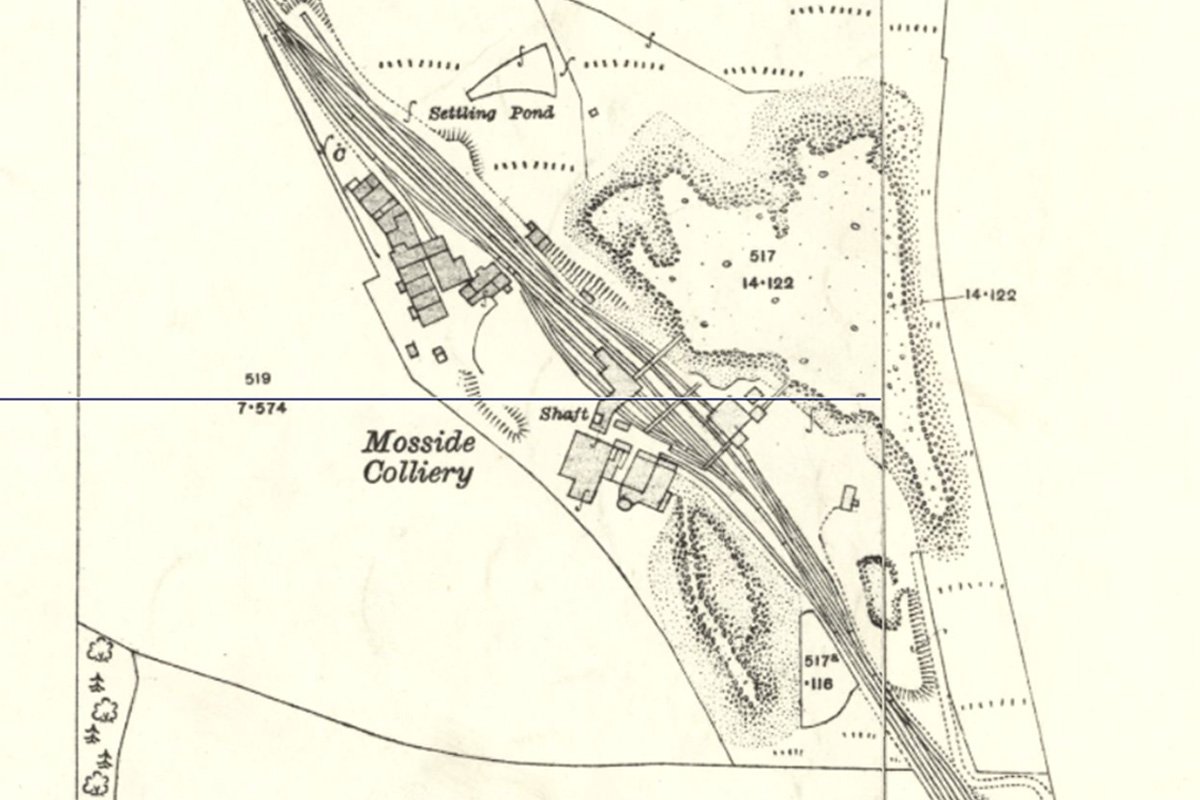

25" OS map c.1914, Courtesy National Library of Scotland

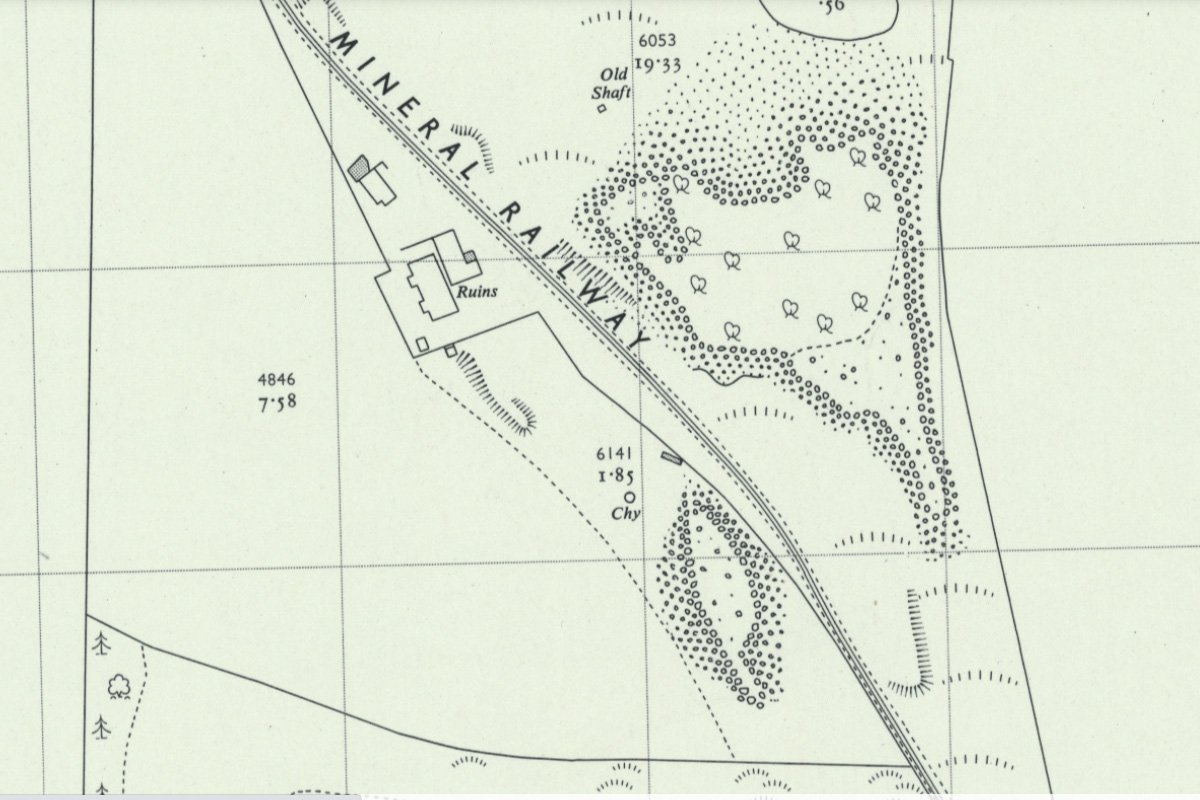

1:2500 OS map c.1956, Courtesy National Library of Scotland

Aerial view

References

Sale of Surplus Colliery Plant at MOSSIDE COLLIERY (close to Bathgate Station N.B.R.) on Tuesday 5th June 1894 at 12 o'clock consisting of Horizontal Engine and Ventilating Fan, Vertical Engine , Winding and Haulage Drums, 2 Worthington Pumps, 2 Double-Acting Pumps,PumpingPipes from 6in to 13in; Working Barrels from 8in to 22in; Pumping Spur Wheels and Cranks, Screwing Machine, Waggon and Hutch Weighing Machines Tram Rails, about 90 ons of Scrap Iron &c, &c Shirlaw Allan & Co have been favoured with instructions from Gavin Paul & Sons to Sell, by auction as above. Trains rom Glasgow (Queen Street Low Level) 9.25 am and Edinburgh (Waverley) 11 am

Glasgow Herald, 23rd May 1894

.......

MOSSIDE COLLIERY

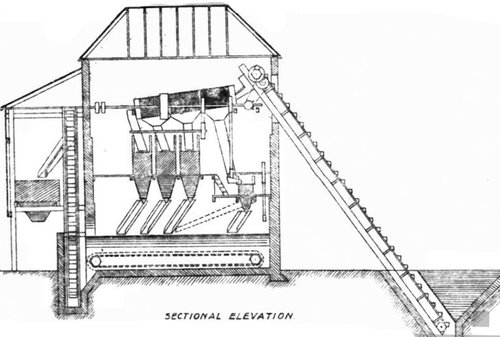

The seams of coal worked at Mosside Colliery are the Jewel and Main. A large coal screening and cleaning plant to be fitted up at this Colliery, he has been recently contracted for and is in course of construction. NEW COAL WASHING PLANT —The outstanding feature in the recent developments at this Colliery is the erection of an extennve Coal Washing Plant, on the Felspar system, which has just been completed. During times of trade depression, and increasing competition, the nescessity of separating foreign material from the coal is a matter of great importance to Colliery owners. This problem forced itself upon the management who, after careful consideration of the most modern plants, adopted the one here described. The order for it placed with Messrs Dickson and Mann, Ltd., Armadale, by whom it has been constructed and erected. All the dross from the dry screening arrangements at Boghead and Riddochhill Pits will be conveyed in wagons to this coal washer. After the new plant has been erected at Mosside Pit the dross will be conveyed by means of scrapers direct from the pit to the washer. The motive power for the Washing Plant is by a pair of horizontal engines. The dross is emptied from the wagons by a hydraulic lift into the Dross Elevator Pit. It is then elevated to a height of 44 feet vertical. An elevator having 60 buckets, each carrying 32-lbs., discharges the dross into a revolving riddle, where it is separated into what is known as Singles, Doubles, Trebles, and Pearls. There are four Washers, on the Bash principle, each class of Nut mai carried into the respective washers by means of "shoots." After being operated on in the Washers the Singles, Doubles, and Tref:des are discharged, over water amines's, into hoppers, from which they are loaded into wagons. The Pearls, after passing into the Felspar Washer, are discharged into a well underneath. This is fitted with a Scraper Conveyor, which takes them along to a pit from which they are again elevated and discharged into a Hopper, and thereafter loaded into waggons. By these processes all the impurities are taken from the coal, and the debris discharged into a setting well. From there it is scraped along to an elevator pit and elevat e d and emptied on the refuse bing

West Lothian Courier, 21st March 1902. See full record

.......

IMPORTANT SALE OF COLLIERY AND ELECTRIC PLANT; 4 LANCASHIRE STEAM BOILERS, 30 ft. by 7 ft. 6 Insured at 100 Ltd. Pressure; 2 PAIRS COUPLED WINDING ENGINES, 22. and 16 In. Cylinders; HORZ. COMPOUND CONDENSING TANDEM PUMPING ENGINE; HORZ. HAULAGE and DRIVING ENGINES; 200 K.W. ELECTRIC GENERATING SET, 500 Volts D.C.; ELECTRIC MAIN and TAIL and MAIN ROPE HAULAGES front 85 H.P.; D.C. MOTORS from 100 H.P., 500 Volts, with CONTROLLERS and STARTERS; LARGE QUANTITY SWITCH GEAR.; 5 D.C. COAL CUTTERS; TURBINE and STEAM PUMPS; 20 ft. GUIBAL FAN; COAL CLEANING PLANT; SAW MILL PLANT; HAND DERRICK CRANES from 3 Tons; WAGGON CART, and HUTCH WEIGHING MACHINES; LARGE NUMBER C.I. PIPES from 15 in. dia.; PITHEAD FRAMES and SCAFFOLDS; CORRUGATED IRON and WOODEN ERECTIONS; C. I., M.I., and STEEL SCRAP, etc,

At BOGHEAD & MOSSIDE COLLIERIES, BATHGATE, On THURSDAY FIRST, 4th August, 1922, at 10.30 a.m. prompt.

SHIRLAW, ALLAN and CO., Auctioneers, Hamilton, have received instructions from Messrs GAVIN PAUL and SONS. LTD., Coalmasters, owing to Stoppage of these Collieries TO BY AUCTIONED, as follows:

3 Lancashire Steam Boilers, 30 ft. by 7 ft. 6 in., by Penman and Co., insured at 100 lb. pressure; Lancashire Steam Boiler, 30 ft. by 7 ft. 6 in., by Penman and Co., insured at 80 lb.; Pair in. Coupled Winding Engenes, by Gibb and Hogg, Ltd.. Airdrie, with 14 ft. Drum and Inglis Overwinding Controller; Pair 16 in. Coupled Winding Engines. with 9 ft. Drum and Inglis Overwinding Controller; Holz. Compound Condensing Tandem Pumping hngine, by Barclay, Kilmarnock,H.Y. Cylinder, 98 in., L.P. Cylinder, 72 in., fitted with Davey's Patent Differential Control Gear; Double. Acting C.I. Surface Condenser, by Barclay, Air Pump, 21 in. Barrel, 9 ft. Stroke, with Connections; 9 Bore. and Vertical Driving and Haulage Engines, from 30 in. to 6 in. cylinders, and Connections; 200 K.W. D.C. Electric Generating Set. consisting of Vertical Twin-Cylinder High Speed Self-Lubricating Engine, by Bellis; and Morrow, Ltd. Birmingham, Coupled direct to Six-Pole Interpolar Compound Wound Generator, by Bruce, .Peebles, and Co., Ltd., Volts 500 , Amps. 400, Switch Board and Connections; 6 Hors. and Vertical Steam Pump', from 14 in. by 7 in. by 9 in. to 71 in. by in. by 6 in; Eleven-Stage Turbine Pump, by Mather and Platt. Ltd., Manchester, for Electric Drive, to Throw about 100 Gallons per minute at 1000 ft. head; 4 Main and Tail and Main Rope Haulages, 85, 45, 27, and 15 H.P., fur Electric Drive; 5 D.C. Coal Cutters by Anderson, Boyce, and Co., Ltd., with Connectional and Spare Parts, 18 D.C. Motors from 100 to 24 Volts with Controllers. Starters and Connections; Large Quantity D.C. Switch Gear, including Mining Unit-Type Distribution Boards, Starting Panels, Flame Proof Switch and Fuse Boxes, Gate-end Boxes, etc.; Large Quantity 37-15 Twin- Core S.W.A. Cable; 20 ft. Guibal Fan, with 16 in. Holz. Driving Engine; 2 Trestle Pithead Frames, 50 ft. and ft. high; P.P. Haulage Frame 35 ft. high, with 6 ft. C.l. Pulley; 3 Pairs Pithead Spider Pulleys from. 12 ft. to 7 ft.; C.I. Grooved Rope Pulleys trom 6 ft. dia., Pair 14 ft. Heavy Steel Built Bell cranks with Steel Built Radius Bar; Coal Cleaning Plant consisting of 2 Self-Acting Resolving Hutch Tipplers', 2 Shaking Screens, 2 Plate Coal Picking Tables and Scraper Conveyor, with Shafting and Connections; P.P. Pump Rods from 14 in. by 14 in., from 28 ft. long; Large Number M.I. Pump Rod Plates 11 in. by 1in and 9 in. by 1in., from 15 ft. long; 20.T0n Beam Waggon Weighing Machine, by Pooley, with 14 ft. Table; 3-Ton Beam Cart Weighing Machine by Avery; Three 30 and 20-Cwt. Hutch Weighing Machines, with 41 ft. and 4 ft. Revolving rabies; 100 Fifty Six lb. Weights; Heavy D.P. and S.P. Pit Cranes; 3-Ton and 13-Cwt. Hand Derrick Cranes; Winding and Haulage Drums from 71 ft. dia.; Saw Mill Plant consisting of Semi-Portable Under-Driven Compound Engine and Boiler 13 ft. 6 in. by 3 ft. in. (over all), Boiler Insured at 100 lbs. pressure: Rack Travelling Saw Bench with 19 ft. Table; 5 E.E. Boiler Tanks from 30 ft. by 5 ft. 6 in. to 213 ft. by 5 ft. 6 in.: about 1500 ft. of C.I. Flanged Steam and Water Pipe, from 15 in. to 6 in., with Bends, Branches and Connections; Large Number Heavy Pipe Bolts, Nuts, Washers and Glands: Steel H. Beams, Angles and Rails; Loose Permanent Rails: C.I. Plates 4 ft. by 2 ft.: Large Number Chains various; Chain and Rope Lifting Blocks from 3 Tons: Detaching 'Hooks for 5-Ton Load; Pipe Lifting Screw; Sinking Kettles; Double and Single Pit Cages; Hutches; Steel Wire Ropes from 2 in. to in... Platelayer's Tools: Fire Extinguishers; Engineer's and Smith's Tools; Large Quantity C.I, MI., and Steel Scrap, Scrap Copper, Brass. etc Corrugated Iron and Wooden Erections of Engine House. Workshop& Offices. etc.; Timber and Corrugated Iron of Pithead Scaffolds, Cleaning Plant Houses. etc.; Large Quantity Timber including P.P. Logs and beams from 12 in. by 9 in.. from 28 ft. long; Planks and Battens: Corrugated Iron Sheets; Timber various; Firewood. etc.

Note.—The Exposers will Load the Material on Railway Waggons Free of Charge. Catalogues from Auctioneer. Hamilton, August, 1922.

Lothian Courier, 18th August 1922