- Badallan pit

- Badallan No.2 mine

- Balbardie - old pits

- Balbardie No.1 pit

- Balbardie No.2 pit

- Balbardie No.2 mine

- Balbardie No.4 pit

- Balbardie No.5 pit

- Ballencreiff fireclay mine

- Ballencrieff - early pits

- Barbauchlaw - early pits

- Barbauchlaw No.1 pit

- Barbauchlaw No.2 pit

- Barbauchlaw No.3 pit

- Barbauchlaw No.4 pit

- Barbauchlaw No.5 pit

- Barbauchlaw No.7 pit

- Barbauchlaw No.9 pit

- Barbauchlaw No.11 pit

- Barbauchlaw No.10 pit

- Barbauchlaw No.12 pit

- Barbauchlaw No.13 pit

- Barbauchlaw No.14 pit

- Barbauchlaw No.15 pit

- Barbauchlaw No.16 pit

- Barbauchlaw No.17 pit

- Barbauchlaw No.18 pit

- Barbauchlaw No.19 pit

- Barbauchlaw No.23 pit

- Barbauchlaw Fireclay and Coal Mine

- Bathgate - old pits

- Bathville No.1 pit

- Bathville No.3 pit

- Bathville No.4 pit

- Bathville No.5 pit

- Bathville unidentified pit 1

- Bathville unidentified pit 2

- Bathville unidentified pit 3

- Benhar (Addie) No.2 pit

- Benhar No.6 and No.14 pits

- Benhar Colliery

- Benhar No.18 pit

- Benhar No.19 pit

- Benhar No.21 pit

- Benhar No.3 pit

- Benhar No.5 pit

- Benhar - old pits

- Benhar unidentified pits

- Benthead No.1 mine

- Benthead unidentified pit 1

- Benthead unidentified pit 2

- Benthead unidentified pit 3

- Benthead unidentified pit 4

- Benthead unidentified pit 5

- Benthead unidentified pit 6

- Bents mine

- Birniehill mine

- Blackrigg No. 1 & 2

- Blackrigg No.3 pit

- Boghead No.1 pit

- Boghead No.2 pit

- Boghead No.3 pit

- Boghead No.4 pit

- Boghead No.5 pit

- Boghead No.6 pit

- Boghead No.8 pit

- Boghead No.9 pit

- Boghead No.10 pit

- Boghead No.11 pit

- Boghead No.12 pit

- Boghead No.14 pit

- Boghead No.15 pit

- Boghead No.25 mine

- Braehead No. 1 pit

- Braehead No.2 pit

- Bridgecastle - early pits

- Bridgehouse - old pits

- Bridgehouse pit

- Brucefield pit

- Camps pit

- Cappers No.1 pit

- Cappers No.2 pit

- Cappers No.3 pit

- Cappers No.4 pit ?

- Colinshiel No.1 pit

- Colinshiel No.2 pit

- Colinshiel No.3 pit

- Colinshiel No.4 pit

- Cowdenhill No.1 Pit

- Craigrigg pit

- Crofthead (Stonehead) No.1 pit

- Crofthead No.2 pit

- Crofthead No.3 pit

- Crofthead No.5 & 6 pit

- Crofthead No.7 pit

- Crofthead (Stonehead) No.7 pit

- Cult pit

- Cultrigg No.1 & No.2 pits

- Cultrigg No.3 pit

- Cultrigg No.4 pit

- Cuthill mines

- Drumcross pits

- Drum No.1 & 2 pits

- Dumback No.1 mine

- Dumback No.2 mine

- East Benhar No.2 mine

- Eastfield No.1 ironstone pit

- Eastfield No.3 ironstone pit

- Eastfield No.3 coal pit

- Eastfield No.4 ironstone pit

- Eastfield No.5 pit

- Eastfield No.6 pit

- Eastfield No.8 ironstone pit

- Eastfield Eagin pit

- Eastfield Engine pit

- Eastfield unidentified pit 1

- East Handaxwood fireclay mine

- Easton No.1 pit

- Eastrigg (Craigrigg) No.1 pit

- Eastrigg (Craigrigg) No.2 pit

- Eastrigg (Craigrigg) No.3 pit

- Fallahill No.3 pit

- Fallahill No.4 pit

- Fauldhouse No.1 pit

- Fauldhouse No.1 (Knowes) pit

- Fauldhouse No.5 pit

- Fauldhouse No.8 pit

- Fauldhouse No.9 pit

- Fauldhouse No.10 pit

- Fauldhouse No.11 pit

- Fauldhouse No.13 pit

- Foulshiels No.1 & No.2 pits

- Gormyre mine

- Goukstane pit

- Greenburn pit

- Greenrigg pit

- Handaxwood No.1 pit

- Handaxwood No.2 pit

- Handaxwood No.3 pit

- Handaxwood No.4 pit

- Handaxwood No.5 pit

- Handaxwood early pits

- Handaxwood unidentified pit 1

- Handaxwood unidentified pit 2

- Handaxwood unidentified pit 3

- Handaxwood unidentified pit 4

- Handaxwood unidentified pit 5

- Handaxwood unidentified pit 6

- Handaxwood unidentified pit 7

- Handaxwood unidentified pit 8

- Handaxwood unidentified pit 12

- Handaxwood unidentified pit 13

- Handaxwood unidentified pit 14

- Handaxwood unidentified pit 15

- Harburn limestone mine

- Harthill No.1 ironstone pit

- Hartrigg or Harthill No.3

- Hartrigg No. 4 & 5 pit

- Heads mine

- Heatherfield No.4 pit

- Heatherfield No.5 pit

- Heatherfield No.6 pit

- Heatherfield No.7 pit

- Hilderston Hill pit

- Hilderston - early pits

- Hopetoun No.2 pit

- Heatherfield No.3 pit

- Hopetoun No.8 pit

- Hopetoun No.9 pit

- Hopetoun No.10 pit

- Hopetoun No.11 pit

- Hopetoun No.12 & 13 pits

- Inchcross No.1 pit

- Inchcross No.2 pit

- Kipps - early pits

- Knowton No.1 & 2 pits

- Latchburn pit

- Leadloch No.1 pit

- Leadloch No.2 pit

- Levenseat No.1 limestone pit

- Levenseat No.2 pit

- Levenseat No.3 limestone pit

- Levenseat No.3 fireclay mine

- Levenseat No.4 fireclay mine

- Levenseat No.1 & 2 fireclay mine

- Levenseat High mine

- Levenseat No.1 limestone mine

- Levenseat quarry limestone mines

- Levenseat unidentified mine

- Loganlea No.1 pit

- Loganlea No.2 pit

- Longford pit

- Mosside No.1 Pit

- Mosside No.2 pit

- Mosside No.3 pit

- Mosside No.4 mine

- Muckraw mine

- Muirhousedyke pit (1)

- Muirhousedyke pit (2)

- Muldron No.6 pit

- Muldron No.7 pit

- Muldron No.8 pit

- Muldron No.9 pit

- Muldron unidentified pit 1

- Muldron unidentified pit 2

- Muldron unidentified pit 3

- Muldron unidentified pit 4

- Muldron unidentified pit 5

- Muldron unidentified pit 6

- Muldron unidentified pit 7

- Muldron unidentified pit 8

- Muldron unidentified pit 9

- Muldron unidentified pit 11

- Muldron unidentified pit 10

- Muldron unidentified pit 12

- Murieston Limestone Mine

- Murraysgate mine

- North Cobbinshaw coal mine

- Northrigg No.2 pit

- Northrigg No.7 pit

- Northrigg No.1 mine

- Northrigg No.2 mine

- Polkemmet No.5 pit

- Polkemmet No.6 pit

- Polkemmet No.8 pit

- Polkemmet No.9 pit

- Polkemmet Colliery

- Polkemmet No.3 pit

- Polkemmet unidentified pit 1

- Polkemmet unidentified pit 2

- Polkemmet unidentified pit 3

- Polkemmet unidentified pit 4

- Pottishaw No.1 & 2 mine

- Redhouse pit

- Riddochhill No.1 pit

- Riddochhill No.2 pit

- Riddochhill Almond Mines

- Snab pit

- South Broadrigg pit

- Southrigg No. 1 & 2 pits

- Southrigg No. 3 & 4 pits

- Southrigg No. 7 & 8 pits

- Standhill No.1 pit

- Standhill No.2 pit

- Starryshaw No.1 & 2 pits

- Stonehead mine

- Stonehead No.1 pit

- Stonehead No.2 pit

- Stoneheap limestone pit

- Stoneyburn No.1 pit

- Stoneyburn No.2 pit

- Tippethill No.1 & 2 mine

- Torbane No.1 pit

- Torbane No.2 pit

- Torbane No.3 pit

- Torbanehill No.1 pit

- Torbanehill No.2 pit

- Torbanehill No.3 pit

- Torbanehill No.4 pit

- Torbanehill No.5 pit

- Torbanehill No.6 pit

- Torbanehill No.7 pit

- Torbanehill No.8 pit

- Torbanehill No. 9 pit

- Torbanehill No.10 pit

- Torbanehill No.11 pit

- Torbanehill No.12 pit

- Torbanehill No.13 pit

- Torbanehill No.14 pit

- Torbanehill No.15 pit

- Torbanehill No.16 pit

- Torbanehill No.17 pit

- Torbanehill No.18 pit

- Torbanehill No.19 pit

- Torbanehill No.20 pit

- Torbanehill No.21 pit

- Torbanehill No.24 pit

- Torbanehill No.26 pit

- Torbanehill No.29 pit

- Torbanehill Garden Pit

- Trees No.1 pit

- Trees No.2 pit

- Trees No.3 pit

- Wallhouse No.1 mine

- Westallan pit

- Westfield No.1 pit

- Westrigg No.1 pit

- Westrigg No. 2 & 3 pit

- Whitrigg No. 1 & 2 pits

- Whitrigg No. 4 Burnbrae mine

- Whitrigg No. 5 pit

- Whitrigg No.8 & 9 mine

- Woodbank Mine

- Woodend No.1 pit

- Woodend No.2 pit

- Woodend No.3 pit

- Woodend No.4 pit

- Woodend No.5 pit

- Woodmuir No.1 pit

- Woodmuir No.2 pit

- Woodmuir No.3 pit

- Woodmuir No.4 pit

- Woodmuir - early pits (south)

- Woodmuir - early pits (north)

Balbardie No.5 pit

A pit in the lands of Balbardie

The 1883 List of Mines records Balbardie No.5 pit as owned by Henry Walker, manager James McPhail, working the Balbardie Coal by the longwall method, employing 10 on the surface and 49 underground, with downcast shaft measuring 14.5' x 7' and 780 ft deep and an upcast measuring 7.5' x 7' and 750 ft deep. It was a non-fiery mine, relied on natural ventilation and was described as newly sunk..

The 1885 List of Mines records Balbardie No.5 (Boghead) pit as owned by Henry Walker, manager James McPhail, working the Balbardie Coal 5½' by the stoop & room method, employing 15 on the surface and 90 underground, with an downcast shaft 14' x 5' and 90' dee p.Upcast was by No.4 It was a non-fiery pit ventilated by furnace.

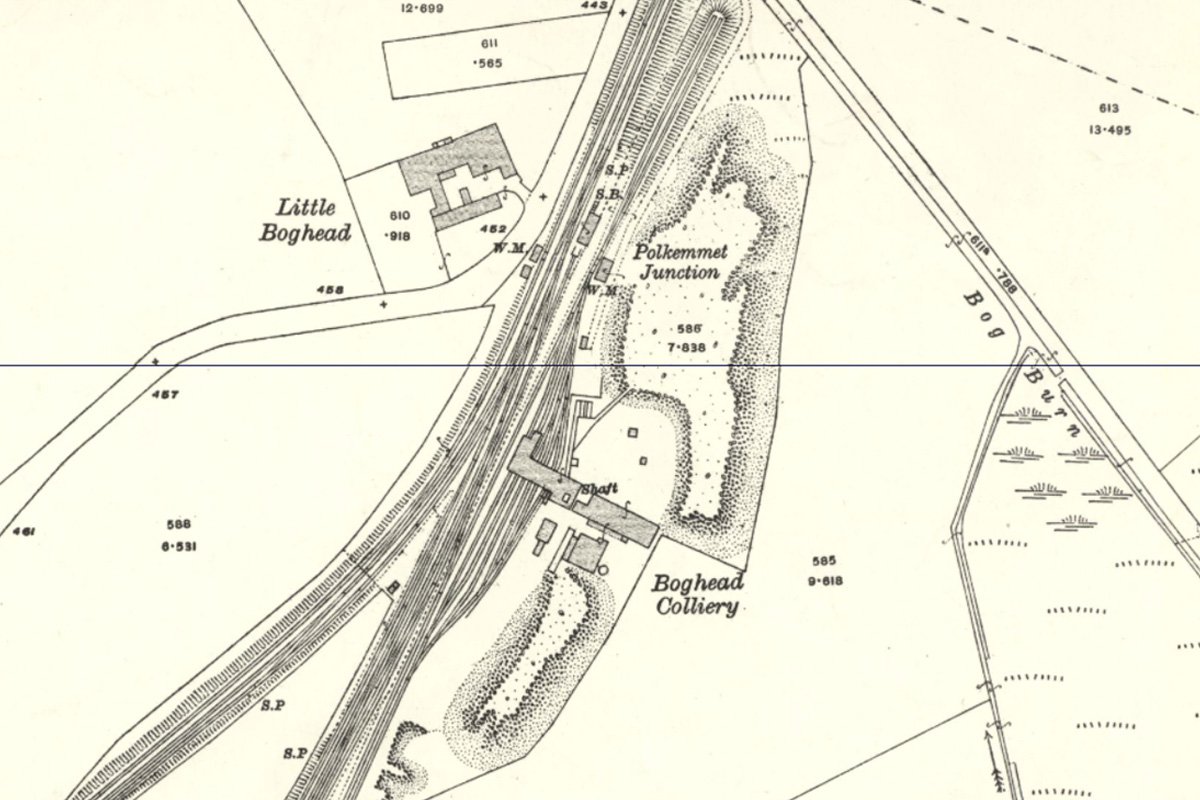

25" OS map c.1895, Courtesy National Library of Scotland

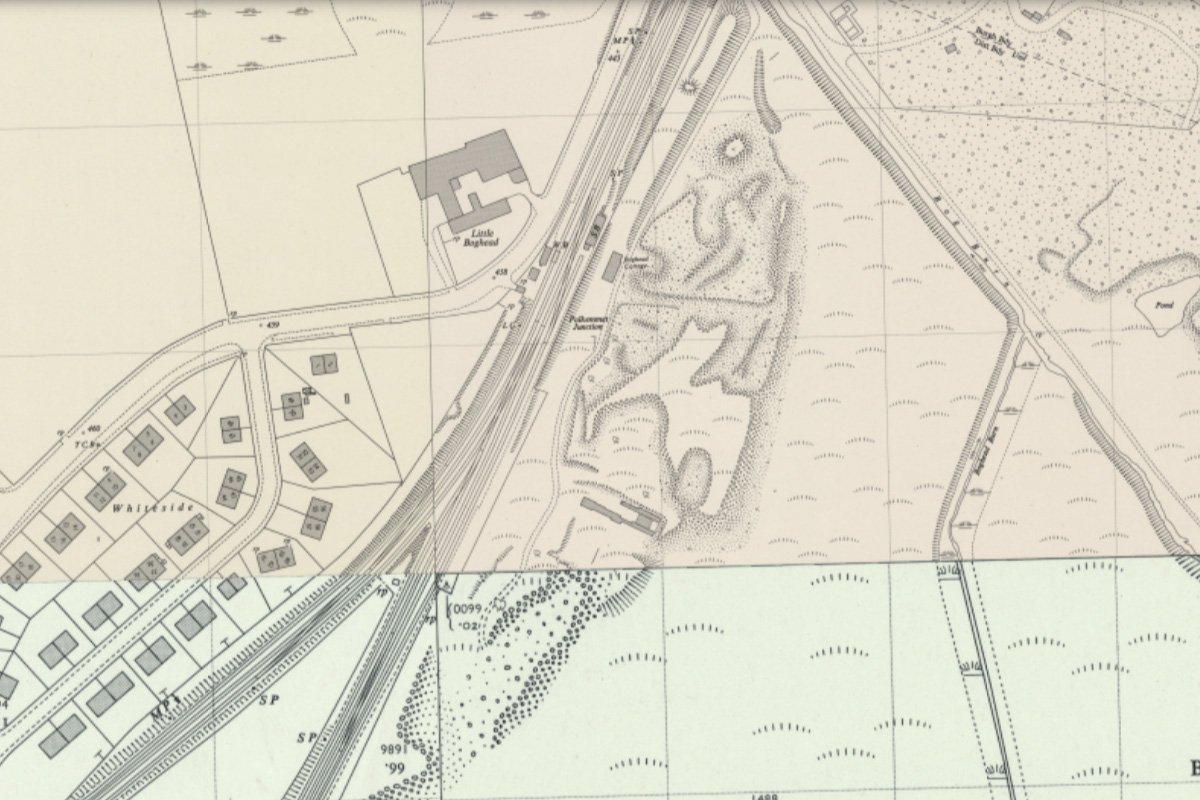

25" OS map c.1914, Courtesy National Library of Scotland

1:2500 OS map c.1956, Courtesy National Library of Scotland

Aerial view

References

BATHGATE - NEW MINE

Henry Walker & Son have been boring on the eastern part of the Boghead estate and have come upon what is knowm as the Balbardie seam at a depth of about 135 fathoms. The seam consists of the gas coal worked at the Messrs Walker's Balbardie pit blackband ironstone of first class quality , and common house coal. There is also a layer of fire-clay and the workings in all will be about six feet. A mine will be driven from the present pit at the Bog on the Balbardie estate, to form a connection with the new pit, and, in addition to the mineral thus wrought out of the same seam at Standhill will in the course of time be worked from the same shafts . It is expected that £ 25,000 will be expended on the new work. At present Messrs Walker are working from their Balbaldie pit mid mine, not only the Balbardie mineral, be also the extension of the seam through the Woodhead estate, and it is stated that the firm intend following its course over 200 acres of the Hopetoun estate. The boring, which has been conducted by Mr Thomas Wilson of Armadale, has been carried, out by steam power and new apparatus. Mr Wilson's machine requires only three men to carry on the operations, and the work has been carried out in a fourth of the time usually taken by the ordinary method.

The Scotsman, 21st February 1880

.......

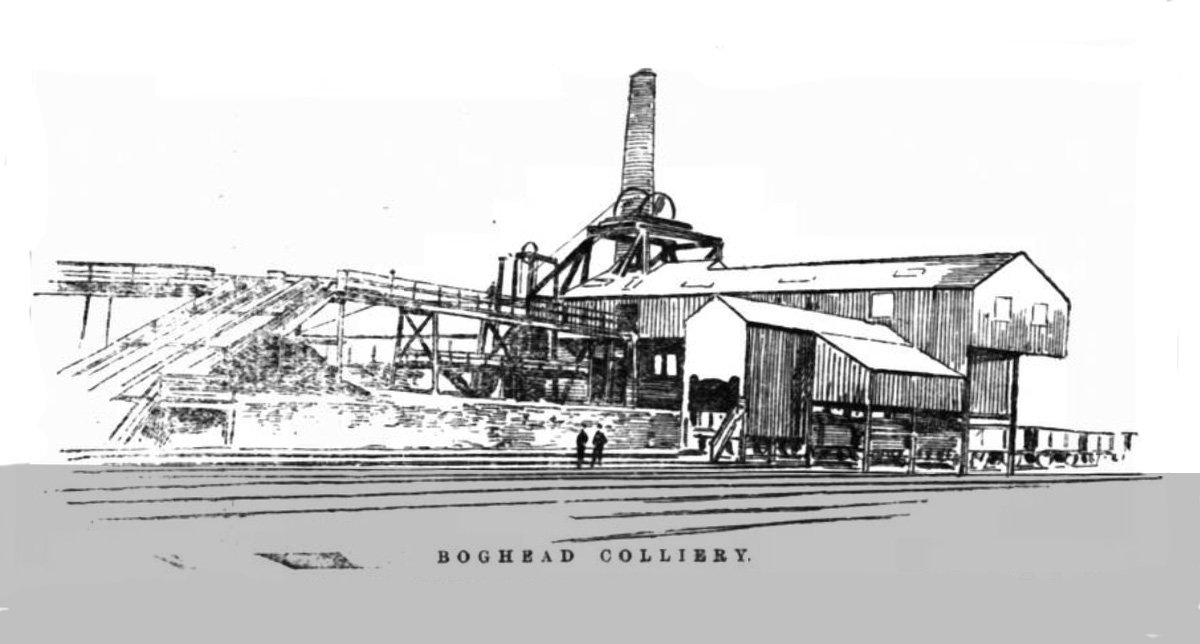

BOGHEAD COLLIERY. The objects of special interest at Boghead Pit are

(1) The Coal Screening and Cleaning Plants, which have been recently erected by Messrs Dickson and Mann, Lid.

(2) A large Compound and Condensing Pumping Engine, made by Messrs Andrew Barclay and Sons, Kilmarnock, the cylinders of which are 38 and 76 inches diameter, with a 9 feet stroke. The engines are controlled by Davers Patent Differential gearing. The Pumps, which are driven by this engine, discharge 30,000 gallons of water per hour from a depth of 900 feet, thereby draining all the underground workings of Boghead and Mosside Pits

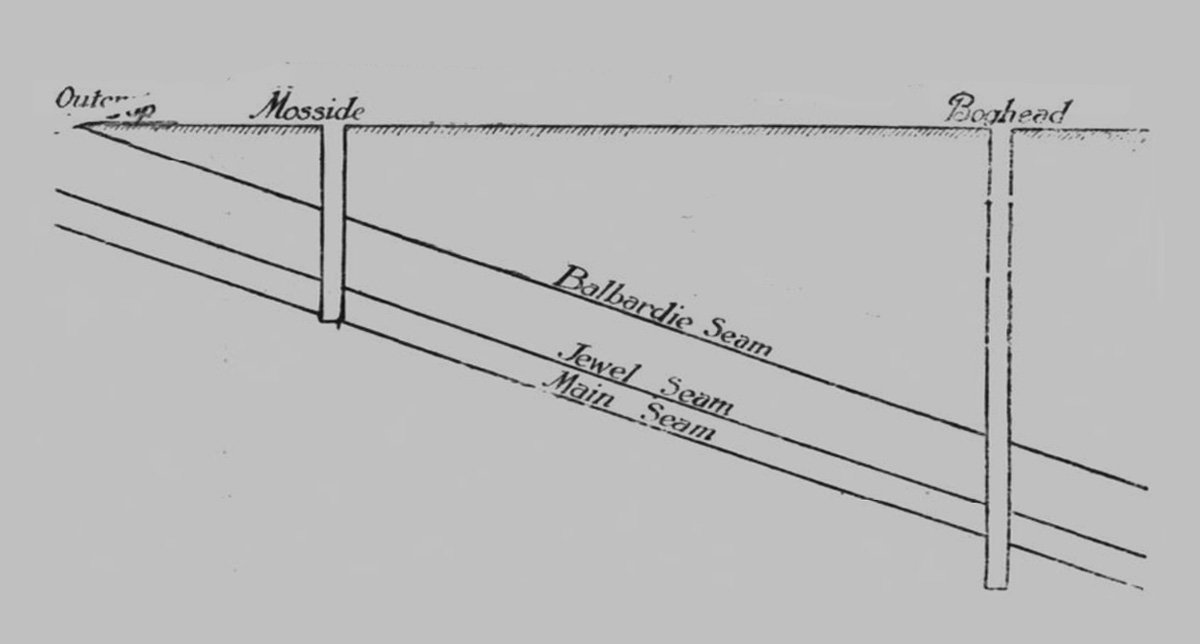

(3) The Coupled Winding Engines which haul the coal from this Pit. These are fitted with Drew's Patent Balance Piston Valve, and are capable of dealing with large output. A powerful Crab engine has also been pit. This is used for handling the heavy pump castings in the shaft. The adjoining sketch shows the relative positions of Boghead and Mosside.