Dorset

The Dorset Shale Oil Industry

Kimmeridge Bay. November 2015.

The Dorset coast, showing sites associated with the shale oil industry, and with areas of Kimmeridge shale shaded blue.

Overview

The bituminous shales that are exposed in the sea cliffs of Kimmeridge Bay, and elsewhere along the Dorset coast, have long been exploited for industrial purposes. The shales at Kimmeridge were used for the production of alum, and fuelled various other industrial enterprises promoted by local landowner Sir William Clavell during the 17th century. Certain seams of shale were sufficiently rich in oil to burn like a coal, and were used in local villages as a domestic fuel. Most notable of these seams was the "Blackstone", a band little more than two feet thick which was often referred to as "Kimmeridge Coal". This could yield over 80 gallons of oil per ton, making it one of the richest oil-producing minerals found anywhere in Britain.

The combustible nature of the shales was evident form the fires that broke out spontaneously along the shale cliffs and could continue to smoulder for many years. Near Holworth, where a small area of oil shale outcropped to the west of Kimmeridge bay, the cliff caught fire spontaneously during. For a period, the smoke and flames emerging from the burning cliff, located across the bay from the emerging seaside resort of Weymouth, became a minor tourist attraction, being was described in one guide as a "miniature Mount Etna".

While it was evident that Kimmeridge shales were rich in hydrocarbons, a succession of short lived business enterprises failed to establish a viable and sustainable industry. The major obstacle seems to have been the high sulphur content of the shales, which could not be removed during refining by the techniques then available. This resulted in oils possessing an extremely objectional smell, quite unsuited for domestic use as a fuel for lamps. This fact was obscured by the surreptitious use of Scottish Boghead Coal by a number of the Dorset-based oil companies, who hoped to evade payment of royalties for the use of processes covered by Young's patent.

The complicated history of the Dorset shale oil industry during the Victorian era was outlined by oil industry expert Sir Boverton Redwood in his treatise; "Petroleum: a treatise on the geographical distribution and geological occurrence etc.". In successive editions published from 1896 onwards, Redwood states:

In 1848, a company was formed under the name of the Bituminous Shale Company, to manufacture lubricating grease, pitch, naphtha, paraffin, varnish, and paint, as well as ammonia, by subjecting the shale to destructive distillation, and plant was erected at Weymouth. In 1854 the property changed hands, and the works were removed to Wareham, attention being concentrated upon the manufacture of manure.

These statements seem to have formed the basis of most subsequent histories of the Dorset oil industry, but are inconsistent with many contemporary records. In particular, Redwood and others appear to have confused the separate histories of the Weymouth and the Wareham oil works.

Much of our knowledge of the early history of the Dorset oil industry comes from the transcripts of two court cases; Binnie v. Clydesdale, held in 1860 and Young v. Fernie which finally concluded in 1864. In each case the defendants attempted to establish that the processes described in Young's 1850 patent for the production of paraffin oil were common practice before that date, and consequently that the patent had no validity. The Clydesdale and earlier cases had established that Young's patent applied only to coal minerals and not to shales found in Dorset or elsewhere. The patent clearly covered the use of Scottish Boghead coal however, and the continued use of this mineral at the Wareham oil works perhaps reflected a misplaced expectation that the validity of Young's patent would be overturned by the Young v. Fernie trial.

- The Burning Cliff at Holworth. A vivid account of a spectacular natural phenominum, expressing a hope that this might attract additional visitors to Weymouth. The Mechanics Magazine, 15th January 1831

- De Buisson's Retort. Extract from the patent specification for a type of process and design of retort that may have been used at oil works in Dorsetshire

- Memoirs of the Geological Survey. The Geology of the Isle of Purbeck and Weymouth. By A. Strachan.1898. A description of the Blackstone and its chemical composition. 1898

- Miscellaneous References; newspaper references relating to prospecting for Kimmeridge shale and other oil operations in the County of Dorset

- Bituminous Shale Co. v. Cassell. Account of the winding up of the company and a dispute over the ownership of land at Wareham Oil Works. The Law Times 11th March 1854

- Binney & Co. v Clydesdale Chemical Co. Extracts from report of the jury trial held in Edinburgh in November 1860 which relate to oil operations in Dorsetshire. Download full document; BP collection 195537

- Young v. Fernie (5) - Testimonies describing the operation of the Wareham oil works, (from 29th February 1864). Reprinted in The Journal of Gas Lighting, 22nd March 1864

- Bituminous Schale or Schistus. Newspaper advertisment for the products of the Weymouth Schiste Works. London Daily News, 23rd February 1850, and The Railway Times, 6th April 1850.

- Excellent Manure. Newspaper advertisment for the products of the Bituminous Shale Co. Ltd. The North Wales Chronicle, 30th November 1850,. The Dorset County Chronicle, 28th August 1851 and The Newcastle Journal, 20th September 1851.

- Hydro Carbon Oil. Testimony of the merits of lamp oils manufactured by the Wareham Oil & Candle Co. Ltd. The Sanitary Reporter, 10th July 1863.

General Descriptions

Court Cases

Advertisments and Testimonials

- Sir William Clavell

- John Braithwaite

- John Ericsson

- Charles Cheffins

- William C. Homersham

2.) Weymouth Schiste Works

The origins of the Dorset shale oil industry lie in France where, in 1838, Alexander Selligue and David Blum patented a process to produce oils by the retorting of shale, and established a shale oil industry based at Autun, in the Saone-et-Loire department of Burgundy. Accounts suggest that Sellgue also experimented with samples of English shale, presumably imported from Dorset. In 1845 Michel De Buisson, who described himself as part-owner and chemist of the extensive oil works at Autun, took out a British patent for a retorting process generally similar to that pioneered by Selligue.

A licence for use of De Buisson's patent was granted to firm involving John Braithwaite, a renowned mechanical and civil engineer. Braithwaite is likely to have been familiar with Dorset and its minerals. As a child, he had assisted his father in a daring salvage of shipwrecked cargo off the coast of Weymouth using a diving bell, and in about.1844 had prepared plans for the abortive Direct London and Exeter Railway. During 1844 and 1846, Braithwaite worked in eastern France to engineer the route of the British-backed Paris and Strasburg Railway, which may have led to his awareness and interest in the new shale oil works at Autun.

Plans to construct an oil works at Weymouth were made public during early 1846 and were said to involve "eminent french scientists", and employ shale quarried from near the Burning Cliff, across the bay from Weymouth. A number of contemporary reports refer to John Braithwaite as part proprietor of the oil works, suggesting that he had partners in the enterprise. One source suggests that Captain John Ericsson (1803-1889), played a major role in setting up the oil works, although this requires collaboration. Braithwaite and Ericsson had previously worked together in various projects, including entering a locomotive in the Rainhill Trials; however Ericsson had emigrated to USA in 1839 where he was later to design the first screw driven steam warship for the US navy.

Braithwaite's difficult financial situation, probably as a consequence of speculation in railway stocks, seems to have delayed progress with the oil works, and in January 1849, following a declaration of bankruptcy, his assets were assigned to a group of three trustees, who seem likely to have been trusted professional colleagues, including the distinguished engineer and surveyor Charles Cheffins.

The trustees appointed civil engineer William C. Homersham to oversee completion of the Weymouth oil works and begin production. Homersham arrived in Weymouth during autumn 1849 and remained there until July 1850. He described that a stockpile of 2,000 tons of shale existed at that time, some of it "Weymouth shale", but the majority from Kimmeridge. Between completion of the works in January 1850, and July 1850, when the works closed, only about 100 tons of shale were retorted. Advertisements for oil products and the "chemical manure" produced as a waste product of the retorting process, featured in the national press, but attracted few buyers. Homersham admitted that he had little experience of chemical engineering and that no chemist was appointed to assist him in his work. Although the advertisements described a range of oil products, these simply reflected the supposed products of the De Buisson's patent process. In reality, only a small quantity of a foul-smelling crude oil was ever produced, which had still to find a buyer several years after the works ceased production.

3.) The Bituminous Shale Company

The Bituminous Shale Company was established by Act of Parliament in January 1848, with powers to lease the minerals of John Clavell Mansell's estate at Kimmeridge, mine shale, and manufacture oil products. The company's board of directors seem to have included many influential figures from the London financial community. From descriptions of the company's processes and products it seems clear that the enterprise was inspired by the French shale oil industry, but it is unclear what links may have existed with Braithwaite's plans for the Weymouth oil works. An article in the Dorset Chronicle (15/07/1864) stated:,

"a company was formed Weymouth some years ago for the working and distillation of this shale. This company was afterwards reconstructed and works on an extended scale erected at Wareham."

Colonel Mansell did not permit shale to be retorted on his Kimmeridge estate due to the noxious smell of the process. A newspaper account suggests that the Bituminous Shale Co. had initially planned to develop an oil works at a waterside site in Poole, where it might be supplied with Kimmeridge shale by sea. Having failed to secure land for this development, it was decided instead to construct works beside the railway at Northport, immediately to the north of Wareham. At about that time, plans were before parliament for construction of docks on the River Piddle at Wareham that might have enabled shale to be transported to the works by water. Failure to progress this scheme left the company with no option but to cart shale along the eight miles of winding country lanes between Kimmeridge and Northport. The high cost of this transport was later cited as the major cause of the company's failure.

The company sought tenders for construction of the Northport works in November 1848, and for contractors to work and transport the shale in February 1849. Oil production probably commenced late in 1849. No direct evidence has been found that the works were equipped with retorts operating under De Buisson's patent. Testimonies given at the Young v. Fernie trial indicate that the works were initially equipped with one or more vertical retorts and ten D-shaped horizontal retorts. Little success was achieved until mid 1850 when 120 horizontal retorts were completed to a design generally similar to those used in gas works.

The crude oil produced was particularly unpleasant. Edwin Pettit, a director of the Bituminous Shale Co. was later to admit "The smell of the oil at Wareham I could not well forget - it was so nasty; you might smell it five miles off". Only rudimentary refining took place to produce lubricants (said to have been used in the local wool industry), a bitumen varnish and other heavy oil products. An instance was cited in which a lamp oil was sold to circus people to light their tents.

The company chose to concentrate on marketing their chemical manure, a ground-up preparation of spent shale produced as a waste product of oil manufacture. Adverts placed in newspapers throughout England and Wales carried testimonials as to the effectiveness of this chemical fertilizer; often from influential landowners who were personal friends of the Directors. Light spirit was also sold as an insecticide, "an invaluable specific against scab, maggot, &c".

Despite this strong marketing effort, the company soon ran into financial problems. In mid 1853, the Shale Manure and Naphtha Co, was launched to purchase the interests of the Bituminous Shale Co. This new joint-stock company shared many directors with the old company, but, for reasons that remain unclear, was wound-up within months of its formation. A further company, the New Bituminous Shale Co. received parliamentary approval early in 1854, but seems to have made little progress. During this financial turmoil various assets of the company were pledged against debts leading to subsequent legal action and a protracted wind-up of the company that continued until 1857.

During the Young v. Fernie trial, George Woolfries testified;

" I remained in the employ of the (Bituminous Shale) company until they gave over and shut up the place in 1853; but the operations were not going on all the time. I was there a twelvemonth after they finished working, just to keep thing straight". "The new company began in April, 1854, and I remained there till October in the same year, when they closed their works".

This new company was presumably the partnership of Ferguson and Muschamp, which, when dissolved in August 1854, were described as "chemical manufacturers and merchants" based in Wareham. John Bell Muschamp was an accomplished entrepreneur with diverse business interests, notable as a partner in Bainbridge and Muschamp, whose shop in Newcastle is credited as being one of the world's first department stores. In 1853 Muschamp was co-patentee of a process for "improvement in making India rubber solution for waterproofing cloths or other articles without the offensive smell produced by the use of naphtha turpentine oils". At the same time he was partner in a india rubber manufacturer based in Crayford, Kent, and a naphtha manufacturer in Millwall, Middlesex. It seem possible therefore that Muschamp's short involvement at Wareham was associated with manufacturing chemicals used in the production of rubberised fabrics.

4.) The South Boghead Company

In January 1857 Vincent Wanostrocht took over the mineral lease of the Kimmeridge estate. Until his bankruptcy in 1852 Wanostrocht had been a partner in a firm of shipping agents involved in the sugar and guano trade through Liverpool. In December 1857, Wanostrocht and French civil engineer David-Clovis Knap formed the South Boghead Company, a public company based in Paris, which traded as Wanostrocht & Co. The company had powerful supporters including Crimean war hero Aimable Pelissier, the Duke of Malakoff, who was then the French ambassador in London. Wanostrocht and his family set up home in a villa in Parkstone, Poole.

Wanostrocht & Co. invested substantial sums at the Kimmeridge mines, constructing a wrought-iron jetty from which shale was loaded into boats, some being taken by steamer to a quay in Poole where it could be transhipped to larger vessels for export. The company marketed the Kimmeridge Blackstone as "South Boghead" coal, rather misleadingly trading on the reputation of the Scottish Boghead coal, which was in great demand for gas production. Consignments of South Boghead coal was dispatched to London, Paris, Barcelona and New York, although it is not known whether repeat orders were received once the true sulphurous nature of the Kimmeridge Blackstone become evident. During a visit to Kimmeridge, the Duke of Malakoff was feted by local civic leaders and during after-dinner speeches, extractant claims were made that mineral reserves at Kimmeridge were "of greater value than the Newcastle coal of England."

Wanostrocht & Co. also took over the Wareham oil works, which soon gained a reputation for producing refined oils and waxes of an excellent quality. Evidence later given at the Young v. Fernie and Binney v. Clydesdale trials suggests that a further grand deception was taking place. While purporting to manufacture these products from Kimmeridge shale it appears that, from about 1858, Scottish Boghead coal was supplied to Wareham and was the source of many of the refined oil products. By this subterfuge Wanostrocht hoped to evade royalty payments for use of Young's patent. It was later stated that the cost of transporting Boghead coal from Scotland to Wareham was no more that the cost of carting shale from the Kimmeridge mines.

Early in 1859, Young wrote to Wanostrocht threatening legal action for infringement of patent. Perhaps as a consequence, the business was sold to Charles Humfrey & Son in January 1860. Charles Humfrey snr. and Charles Humfrey jnr. were described as "oil manufacturers and candle manufacturers of Suffolk-grove, Southwark" who had been associated with a variety of oil businesses in Middlesex and Surrey, and had filed various patents associated with oil manufacture. In February 1861 Young sought an injunction to restrain the activities of Humfrey & Son, however before action could be taken, Humfrey & Co. were declared bankrupt, having mortgaged their business to a George Wills.

5.) The Wareham Oil & Candle Co. Ltd.

The works and interests of Humfrey & Son then passed to the Wareham Oil & Candle Co. Ltd, which was established in 1861 with George Wills, as the main shareholder.

Richard Edmund Southby, an analytical chemist, was manager or managing director. The company continued to manufacture oil from Scottish Boghead coal, and produced a "Hydro Carbon" lamp oil and candles that soon gained a reputation for excellence.

In 1863, the company constructed a crude oil works at Drumgray near Airdrie in Scotland where a coal shale was used to produce crude oil. The intention was to convey produce by rail to the port of Bo'ness from where it would be shipped to Poole and thence to Wareham for refining. Advertisements in the Scottish press by agents of the company suggest that partly refined products were sold directly to the Scottish market.

In July 1864 Young obtained a court degree prohibiting the Wareham Oil & Candle Co, Ltd from producing paraffin oils from Boghead coal. By that time however, operations at Wareham oil works had been severely disrupted by a fire in April 1863, and in April 1864 the directors had resolved to wind-up the company.

This seems to have marked the end of production at Wareham oil works, which were stripped of equipment, and put up for sale in 1868. Some of the staff at Wareham found new employment in the emerging Scottish shale oil industry. By 1871, Richard Southby, (previously the works manager at Wareham), appears to have been in charge at Handaxwood oil works in Whitburn parish, West Lothian, while George Woolfries, (previously a foreman at Wareham) was a refinery foreman at the nearby Benhar Oil Works.

6.) Emmens, Brothers & Co.

Following failure of the Wareham Oil & Candle Co. in 1864, there is no record of oil shale being worked at Kimmeridge until late 1871 when the local press reported on the re-emergence of the industry following discovery of "a new cheap process of extracting the oil from the shale by atmospheric pressure". This was presumably a patent taken out by Stephen Henry Emmens, whose company, Emmens, Brothers & Co. had taken over the lease of the Kimmeridge mines. Emmens was also promotor and managing director of the West of England Fire-clay Bitumen and Chemical Co. Ltd, whose shareholders were invited to view the "Blackstone mine in Dorset-shire" in January 1872.

The West of England company offered to supply this "Kimmeridge coal" to businesses in London at 25s per ton delivered, and are known to have supplied London gas works. The company's main intention was however to use Kimmeridge shale and other minerals in various processes to be conducted in the company's works near Calstock in Cornwall. It appears that Emmens, Brothers & Co. were contracted to supply Kimmeridge shale shipped to Calstock Quay on the River Tamar at a fixed price per ton

West of England company's prospectus describes how the Kimmeridge shale would be used to produce a bitumen that would be combined with Cornish granite and other minerals to produce asphalte and other paving materials using another process patented by Emmens. The production of bitumen would also yield naphtha, burning and lubricating oils. The company was successful in establishing a major arsenic works at Greenhill near Calstock, supplied by ores from a number of its mines, and also built a fireclay works. There is no evidence however that they went forward with their plans to produce asphalte, bitumen and oils, and it remains unclear whether Emmens Brothers & Co worked Kimmeridge shale in any significant quantity.

Emmens and his companies were declared bankrupt in 1875. In the early 1880's the self-styled "Dr Emmens" emigrated to the USA established a reputation as a prominent metallurgist, and set up a number of chemical businesses. The most controversial of these was the Argentaurum Laboratory which operated a secret process that allegedly transmuted silver into gold. Emmens has been described as "the last British alchemist".

7.) The Sanitary Carbon Co. Ltd

In 1876, The Sanitary Carbon Co. Ltd was formed to manufacture a type of coke from Kimmeridge shale that could deodourise and remove colour from treated sewage effluent more cheaply and effectively than the animal charcoal then in use. This "sanitary carbon" seems to have been produced as the by- product of gas production using Kimmeridge Blackstone. A press release following a trial of the material at a London sewage works stated that the company "owns some 1,200 acres of the district on the Dorsetshire coast where the famous Kimmeridge shale deposit is found." however no other evidence has been found to confirm that the company held the lease to work Kimmeridge shale, or worked it in significant quantities. It might be imagined that the sanitary carbon material might be manufactured at a gas works that had been supplied with Kimmeridge shale, rather than requiring the company to operate their own works.

This enigmatic company was short-lived, but set a legal precedent in company law. In the matter of the Sanitary Carbon Co. "a single shareholder, named Mr. Worswick, was the only person present at the meeting and he also held proxies for all the other three shareholders. Mr. Worswick voted himself into the chair, proposed a resolution to wind up the company voluntarily, declared the resolution passed, and appointed a liquidator. The purported passing of a resolution to wind-up the company was set aside because on the facts there had been no meeting and a compulsory winding up order was made."

8.) Kimmeridge Oil & Carbon Co. Ltd.

Mineral statistics for 1883 record that C. De Grette & Co, operated a mine at Kimmeridge subject to coal mine regulations and that the manager was C. Beaumont. This firm may have been a precursor of the the Kimmeridge Oil and Carbon Company, formed in 1882 to work minerals at Kimmeridge, and to develop an oil works on the former Sandford clay and pottery works. The company is said to have established the mines in the vicinity of Clavells Hard, and produced Blackstone for sale to gas works, for oil production, and for manufacture of "sanitary carbon". A Geological Survey memoir, published in 1898, credits Charles Beaumont for information on the company's products.

The Sandford works and the brick making machinery that it contained were put up for sale by the company in 1887; the sales notice offering no evidence that oil was ever produced on the site. Annual mineral statistics indicate that Kimmeridge shale was shipped from Dorset in very modest quantities during the 1880's. A thousand tons were recorded in the 1882, the company's first year of operation, quickly subsiding to a few hundred tons annually, with a final entry of 70 tons for 1892. The company was wound-up in 1893, marking the end of commercial mining of shale at Kimmeridge.

At the same time that the Kimmeridge Oil & Carbon Co. Ltd were redeveloping the Kimmeridge mines, William Manfield was exploring the oil shale resources of his estate at Portesham, twenty miles to the west. Although substantial effort went into sinking shafts, these were never developed to commercial production.

9.) 20th Century proposals

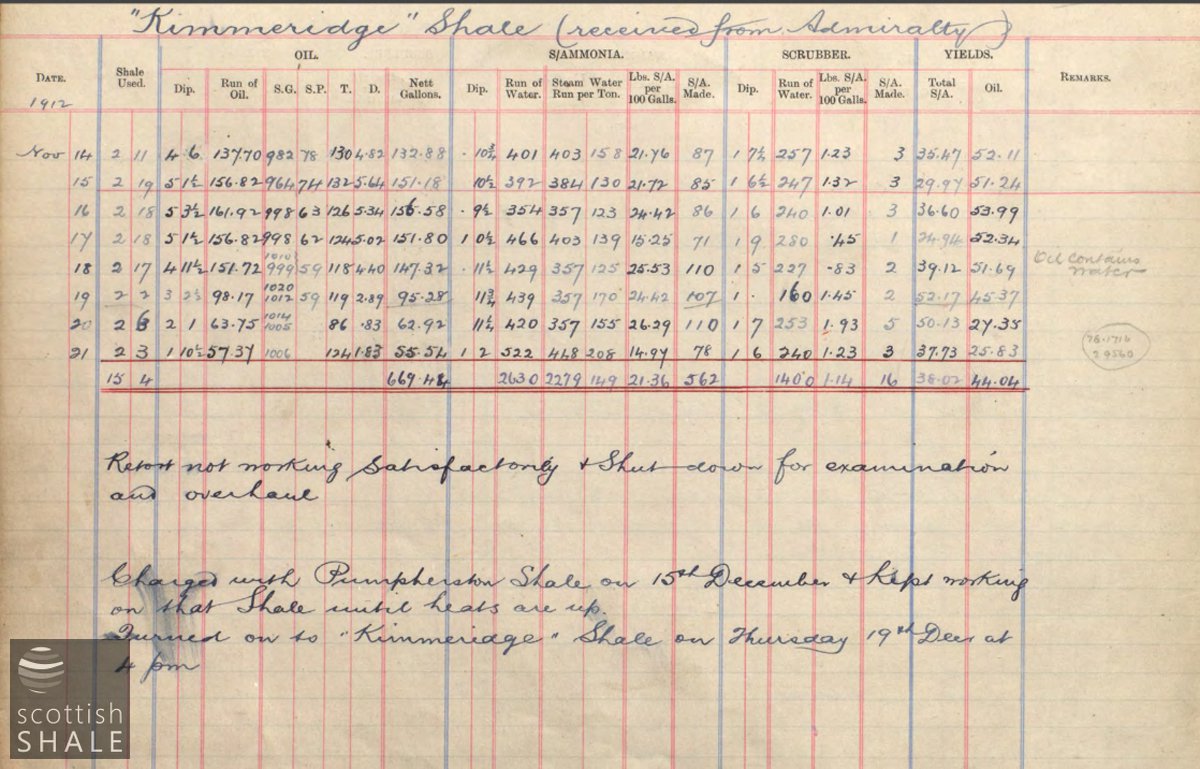

The approach of the First World War brought renewed interest in oil production from Kimmeridge shales. Winston Churchill, then first Lord of the Admiralty, campaigned to secure supplies of oil for the British Navy from "home sources" independent of the foreign interests that then controlled much of the oil trade. He encouraged home production of oil and spoke of the wealth of oil shales that remained unexploited in Scotland, Lincolnshire and Dorset. Following outbreak of war, the government became increasingly concerned about oil supply to the navy and to strategic industries, and from1916 took increasing control over the British oil industry.

In May 1914, shortly before the outbreak of World War One, the British Isles' Oil Producers Ltd. (company No. 13526 with a share capital of £1,000,000) was promoted with the intention of producing oil using the Del Monte retorting process from Scottish shale, Irish cannel coal, and from Kimmeridge shale to be mined at Brandy Bay, South Tyneham, a little west of Kimmeridge. A fifty year lease of these shale beds was transferred to the new company from the Brandy Bay Mining Co. Ltd., which had secured a lease of the minerals in the previous year.

1917, an expert working party reporting to the Ministry of Munitions recommended the establishment of new oil works employing low-temperature Del Monte retorts, however due to costs and labour requirements these plans were dismissed as impractical. The British Isles' Oil Producers Ltd seems to have made little progress and was dissolved in 1920.

In further efforts to boost home produced oil, the Ministry of Munitions commissioned studies to assess the potential of using Dorset oil shales. This included the drilling of a sequence of cored boreholes close to the outcrop of the 'Blackstone' between Portesham and Corton. A series of lease documents dated between 1917 and 1921 (now held in the Dorset Records Office) record mineral leases assigned to the "National Union Oil Co. Ltd." and the "Ethelburga Syndicate", which presumable relate to this prospecting activity.

The studies conducted by the Ministry of Munitions eventually concluded that the productive seams of oil shale in Dorset were thin, there was a lack of labour to work them, and that the sulphur-rich oils produced would be of limited use. Despite this conclusion, there continued to be great interest in exploiting the Kimmeridge shale following the war

According to a newspaper account, German prisoners of war were employed to dig exploratory shafts to the oil shale at Coryates, near Portesham, while in 1922, the Shell Oil Co. undertook trial borings to oilshale near H.M. naval dockyard Portland. The greatest progress seems to have been made by the Kimmeridge Shale & Oil Co. Ltd, which was formed in 1920 and took a lease of minerals at Bincome. Various shafts were sunk by the company, trial loads of shale were tested, and experiments carried out on methods of processing the resulting oil. A sensational account of a deathbed revelation of a secret process appeared in the popular press in May 1924:

"The sudden death of Professor H. T. Burls, the eminent geologist, has created profound regret in scientific circles. It was known that the professor had been overworking himself experimenting on a secret process for eliminating sulphur from Dorsetshire shale. His disclosure of the secret when he was on the verge of death has been followed intense activity in the laboratory".

Despite this national exposure, the company made little progress.

Further schemes emerged to 1930's. In 1934, newspapers reported charges against a Dr. Marco Marconi for obtaining money under false pretences. It was said that two years previously, the Italian scientist had developed a new process for extracting oils from shale which was then employed by the “Dorset Shale Petrol Syndicate”. It is not known if this firm was associated with “Dorset Shale Products Ltd,” a company that was also formed in 1934.