The Remarkable Torbanehill Mineral

Exploring the remains of the Torbanehill pits

F22012 - first published 14th June 2022

The “Torbanehill Mineral”, “Torbanite”, “Boghead Cannel Coal”, and many other names were used to describe an unusual mineral that was found in an area south west of Bathgate. It was exceptionally rich in hydrocarbons and became highly sought after for the production of gas and oils. A series of high profile court cases during the 1850’s and 60’s involved some of the leading “experts” of the day, and ensured that the name “Torbanehill” became known around the world. The lands of Torbanehill have changed substantially over the last 150 years, yet it is still possible to find a few traces of the industry that made the area world famous.

From the 1820’s, cannel coals (also known as parrot coal or gas coal) were used for the production of town gas. Seams of cannel were often found alongside seams of common coal, but they had a very different appearance and consistency, and yielded very much more gas when heated in a gasworks retort. Good quality cannels were found in only a few locations, and in seams that were usually narrow and fickle – varying unpredictably in thickness and sometimes disappearing altogether.

Prospectors looking for ironstone and coal to supply the ironworks of Lanarkshire surveyed much of the West Lothian coalfield during the 1840’s. An unusually rich cannel coal was discovered on the Boghead estate in about 1846 although the seam quickly petered-out and the workings were abandoned. Subsequent bores and investigations revealed that the coal that outcropped near Boghead extended over an area of about three square miles; westward towards Armadale and south to Torbanehill. The seam was rarely more 18 inches thick at the centre of this basin and tapered off to more than a few inches thick at it’s margins. The Boghead coal proved richer than any other cannel found in Britain, and all manner of hype and myth developed around this “remarkable and enigmatic mineral”. It commanded a high price, and for a period was exported to enrich gas production at works throughout Britain, Europe and as far as the east coast of the USA. In 1851 local papers reported that at a site close to the Boghead “an extensive chemical work is in course of erection by an English firm”. This, of course, was the pioneering oil works established by James Paraffin Young and his partners, which further fuelled the demand for the Boghead coal, and added to the mystique surrounding it.

Some of the best Boghead coal lay within the Torbanehill estate of William Gillespie. Various investigations during the 1840’s had concluded that no useful seams of coal or ironstone existed within the estate, however in 1850 Gillespie signed an agreement assigning mineral rights to his land to the Falkirk-based coal and iron master William Russel & Son. Russel had already secured the mineral rights of several neighbouring estates, and (unlike Gillespie) seems to have had a good inkling of the value of the Boghead coal that lay beneath Torbanehill. Once pits were sunk and their riches became apparent, Gillespie sought to renegotiate the terms of the lease and secure greater royalties, asserting that the Boghead coal (or “the Torbane mineral”) was not coal but a completely new form of mineral that was not covered by the existing lease agreement.

In a long sequence of legal actions, all manner of scientific experts were called upon to present their opinion on whether Boghead coal was or was not coal. Some of these fine Victorian gentlemen visited the pits to view mining operations first hand, and their testimonies describe details of grubby everyday operations that might not otherwise have been recorded.

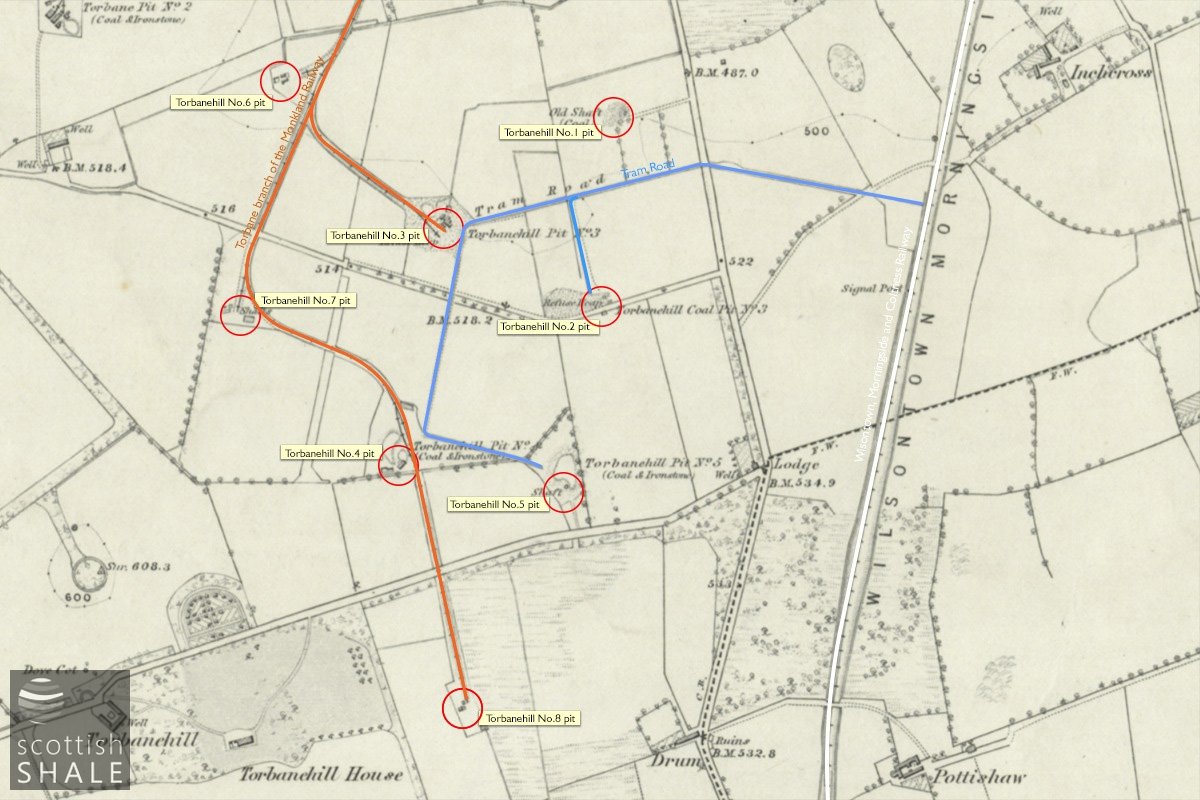

Location of the Torbane Pits, plotted on the 6" OS map c.1855, courtesy of National Library of Scotland

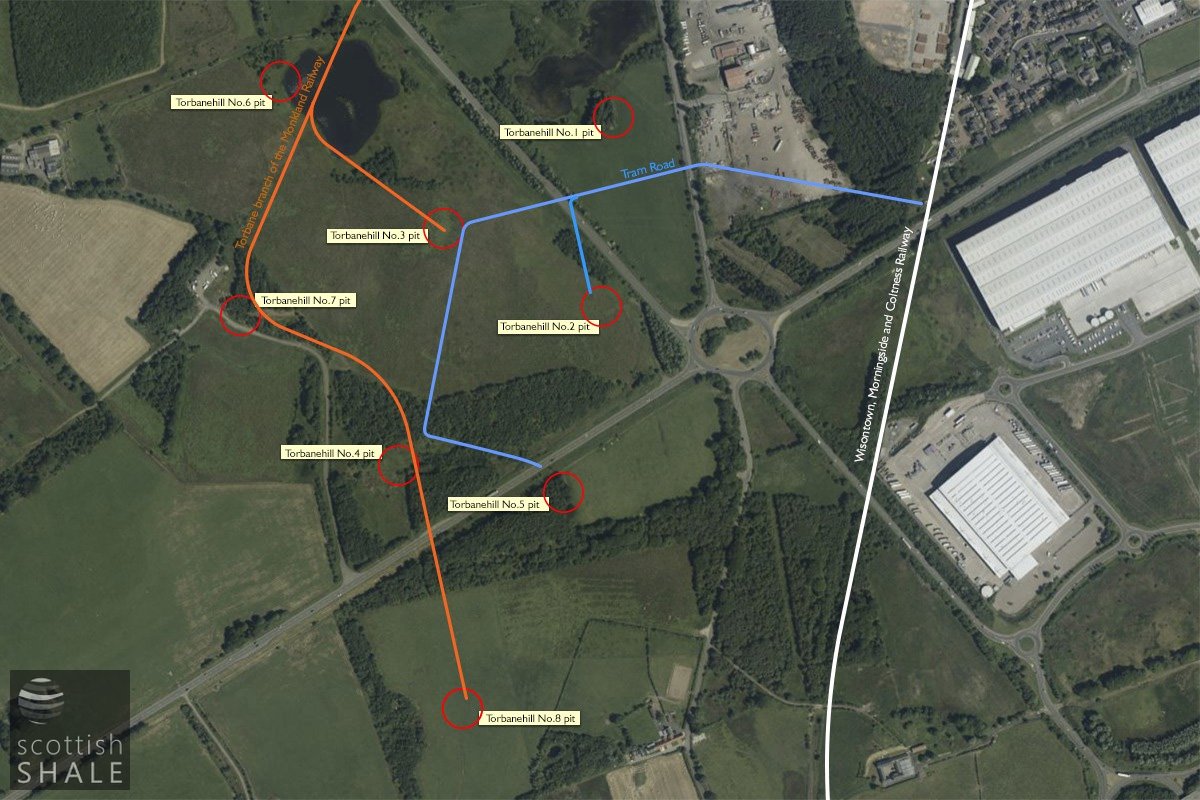

Location of Torbane Pits, plotted on recent aerial view

One of these visitors was Thomas Stewart Traill MD, professor of medical jurisprudence at Edinburgh University. He described his visit to Torbanehill No.2 pit in 1853. Having been lowered to the pit bottom, little more than 30 metres from the surface, he noted that the workings dipped at an angle of 1 in 12 and were so low that it was not possible to stand upright. To reach the working face he “had to lie at full length in a truck and be leisurely let down the incline”. It sounds that this upright gentleman enjoyed his underground experience. A rather different is impression is given in the testimony of a number of miners who explained that the Boghead coal had an intense gas-like smell which, in the confined spaces of the mine, caused headaches and sometimes vomiting.

Boghead coal was very different in nature and consistency from common coal or shales, and the seam (seldom more than 18” thick) usually formed a solid slab of fine-grained material. This tough mineral had to be broken up into to cubic blocks within the confines of underground workings little more that four feet high, before being hauled to the surface. Dr. Trail described piles of these blocks (“varying in thickness from 1 foot 4 inches to 1 foot 11inches”) lying around the pithead.

By 1854, when the first ordnance survey map was produced, there were eight pits on the Torbanehill estate, two of which were already worked out. Each shaft (which were between 20m and 48m deep) was equipped with a steam winding engine, except for No.4 which was so shallow that a horse gin sufficed. A number of “water engines” kept the workings dry. A tram road linked the earliest pits (No.1 to No.5) with a siding on the Wilsontown, Morningside and Coltness railway (completed in 1850), but within a few years most pits were also linked by the Monkland Railway Torbane branch.

By 1870 most of the Boghead coal in the Torbanehill estate had been worked out, other than that left to support Torbanehill house, which (for obvious reasons) had been excluded from Russel’s lease. In a bizarre sequence of events William Gillespie then employed others to mine beneath his house, and stockpiled a huge mound of Boghead coal within his walled garden. This was sold in 1872, but before purchasers had opportunity to take it away, the precious heap was mysterious consumed in a huge fire.

While Torbanehill House slowly subsided, the Torbanehill pits (and Boghead coal pits in neighbouring estates) lay abandoned, and nature gradually reclaimed the landscape.

The new century brought a realisation that the Torbanehill lands contained valuable fire-clay, which was in great demand to feed the brickworks of Armadale. The site of the old Torbanehill No.7 became the pithead of Northrigg No.7 pit (and subsidiary mines), while Drum No.1&2 fireclay mines were sunk near the site of the old Torbanehill No.8 pit. Railway lines were relaid to serve this new industries. United Collieries, and subsequently United Fireclay Products, continued production at these sites until the 1950’s (Drum) and 60’s (Northrigg) until these too were allowed to fall derelict

View from the Whitburn Road towards the site of Torbanehill No.1 pit, and the Half Loaf pond.

The bing of Torbanehill No.1 pit - among the trees

Half moon pond - looking towards No.1 pit

Torebanehill No.1 pit bing

Torebanehill No.1 pit bing

A resident of Half Loaf Pond

Pit waste from Torbanehill No. 5 pit

Pit waste from Torbanehill No. 5 pit

Pit waste from Torbanehill No. 5 pit

Route of railway to No.8 pit

Site of No.4 pit

View towards Torbanehill No. 6 pit

A third phase (and final) phase of mineral extraction took place during the 1980’s and 90’s when much of the lands of Torbanehill, either side of the A706 (the old A8), became huge opencast quarries, working out what remained of the coal and fireclay reserves to supply what remained of Armadale’s brick-making industry. This cleared most scars of past industry, but it is regrettable that the remedial works have left flat, featureless and impassable expanses of reeds and rushes in places. Roads have also sliced across the landscape, starting in the late 1920’s with construction of the great A8 trunk road then, during the 70’s its successor the M8. Later, the unrealised ambition of the A801 sliced across from north to south on a high embankment that blocks other routes of travel.

Exploring the present-day mess of roads, bogland and conifer plantations, it is difficult to imagine the rural landscape, with its little pitheads and rickety tram-roads, that existed at the height of Torbanehill’s fame 160 years ago. The only tiny splinter of this lost landscape survives, between the two arms of road (the A705 and the B7002) that stretch north from the Boghead roundabout. Here swans, coots and moorhen frolic about in the tree-lined Half Loaf pond while traffic rushes past on either side. Hidden among the trees are a couple of heaps of mine waste, marking the site of the pioneer Torbanehill No.1 pit, sunk in about 1850. These shallow workings never fulfilled their promise and were abandoned after only a year or so of operation.

Through time, the ground to the north of the shaft subsided to create an area of wetland that was periodically flooded by the Boghead Burn. According to WLDC Councillor Allister Mackie, it became known locally as the Daisy Pond – some days you see it, some days you don’t ! Quite a wit. Work was done to retain the water level of the “Half Loaf Pond” and in 1988 thousands of trees were planted around its margins by job creation teams to create a community nature reserve. It’s a little piece of heaven; if you can ignore the roar of traffic and the intrusion of overhead power lines.

Beneath the trees on the water’s edge, the rounded profile of the old No.1 pit bings survive largely unchanged, and burrowing beasts sometimes bring fragments of the “remarkable mineral” to the surface. Even after a century and half of weathering, the remarkable Boghead cannel coal still burns like a candle.